What is Fiber Laser Cutting?

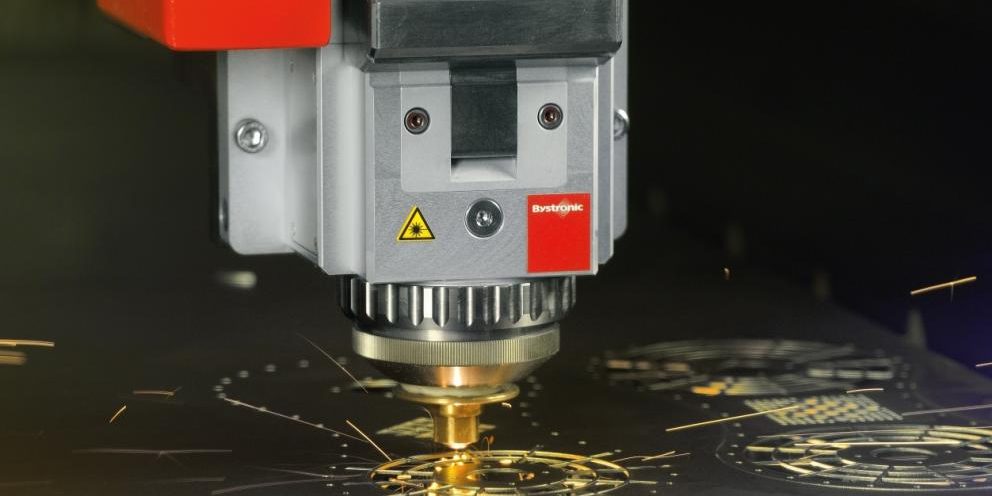

Fiber lasers are the most efficient way in laser cutting. The laser beam is created by an active fiber and transmitted over a transport fiber to the machine cutting head. Fiber lasers are significantly smaller than CO₂ lasers and generate several times the power from the same amount of current. A fiber cutting system is primarily suited for processing thin to thick sheet metal from steel, stainless steel, aluminum and also other non-ferrous metals (copper and brass). See our 3Kw fiber laser in action:

What are the benefits to Fiber Laser Cutting?

- Cost. Fiber laser is delivered through a laser optic cable instead of mirrors and channel used by CO2 laser cutting machine. Reducing power loss and increasing energy efficiency, lowering production costs.

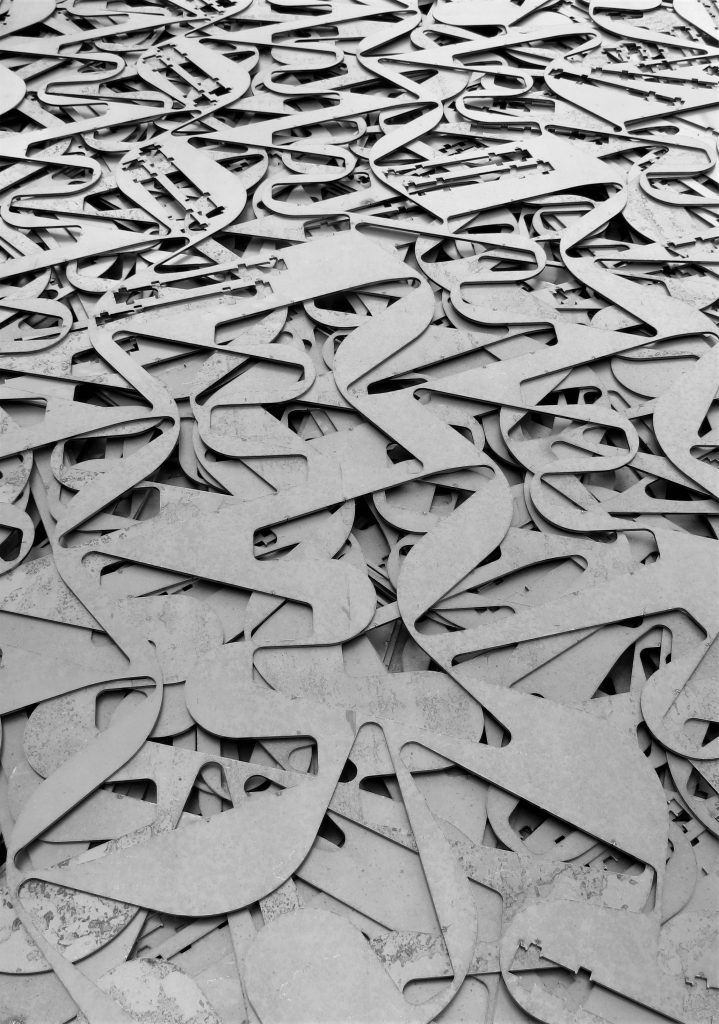

- Cutting Edge. Falcon Precision are well known as a specialist in manufacturing electronics cases for many industries including medical, industrial computers & military. This requires a high volume of thin sheet metal to be cut fast. Our laser is able to cut a variety of materials with a clean edge, requiring no additional de-burring operations.

- Interchangeable beds. Our fiber laser machine has a dual interchangeable platform where materials and finished cutting sheets can be loaded/unloaded whilst the machine is still cutting. Reducing downtime.

- Maintenance. Our fiber laser requires little maintenance and downtime compared to a CO2 laser, saving worry and money. A CO2 laser machine needs regular and annual maintenance with components replaced, which can cost thousands over a year.

- Reflective Material. One of the major problems when using a traditional laser is in regards to reflective material. There is the chance a laser may bounce off the reflective material, which in turn will damage the equipment. Due to this, traditional lasers are not often used when cutting brass, aluminum and copper. With fiber optic lasers though, this reflective material problem is no longer an issue, which in turn allows for the cutting of these materials.

Click here to see the type of work we can offer in our showroom.

How to take advantage

One of the goals when designing for manufacturing is to achieve a simple solution rather than a complex one. After all, complex designs are more difficult to manage, increase the chances of errors and generate waste in the form of materials, energy, labour and time. Laser cutting is a suitable tool for creating all shapes and sizes of components and is one of the most efficient and cost effective fabrication methods. Complex cuts with superior edge quality can be accomplished accurately with fiber laser cutting. Precision laser beams are capable of creating close tolerance components in a quick, clean and efficient manner with minimal operator intervention.

To see how Falcon can help your company’s metal cutting requirements, click the link below to contact us directly.