High Speed CNC Punching for Medium to Large Volume Production

CNC Punching is not just a fast and cost effective method of creating holes in sheet metal for medium to high volume production batches. Our TruPunch 3000 S11 can do much more.

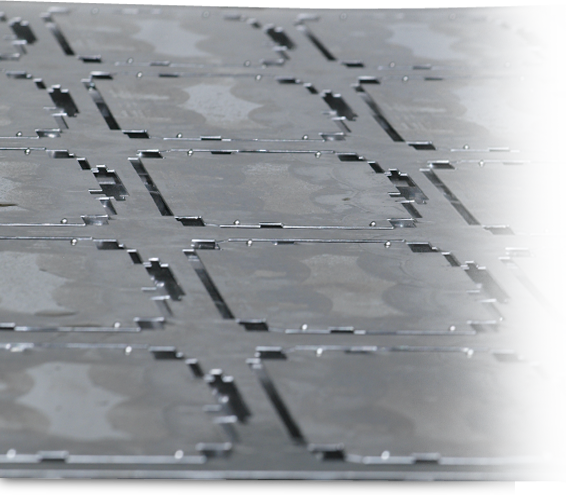

The punching process forces a steel punch through the material into a die thereby creating the cut-out. A nibbling process can also be used where the punched holes overlap leaving cut-outs and profiles in multiple shapes.

Our S11 has a 17 fully indexible tool stations, all of which can be fitted with multi tool stations. Potentially holding up to a massive 170x tools, capable of punching 8.5x per second.

Along with a superior hit rate, the S11 can tap holes, put in 90 degree folds, create complex joggle folds, de-burr, chute completed parts into the parts bin, countersink, counterbore, emboss part numbers and much more. And with fitted sheet loader/unloader, all this can be run over night with lights out production.